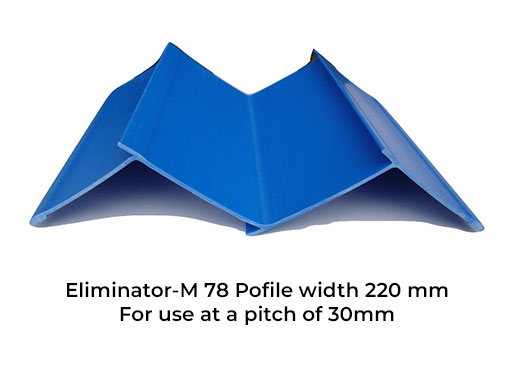

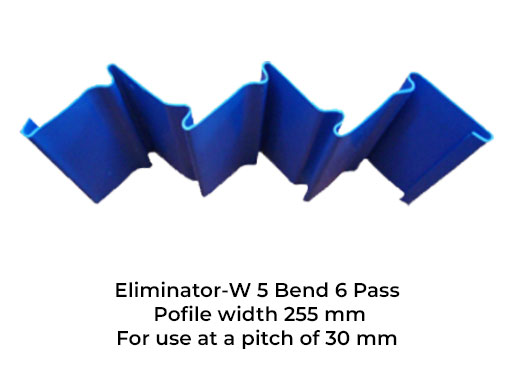

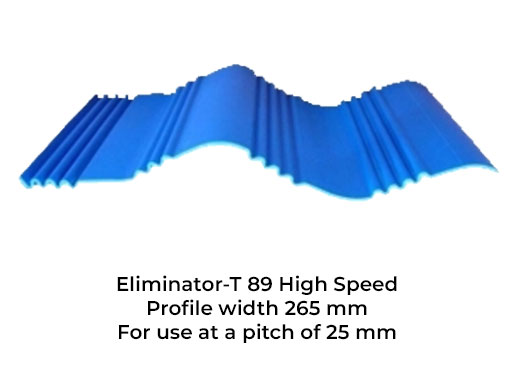

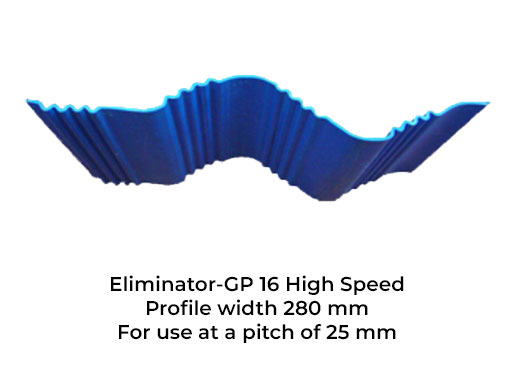

PVC eliminators & Louvers

PVC Mist Eliminators and Louvers are designed for applications in humidification and ventilation systems

They find utility in various settings such as air washers, humidification plants, ventilation systems, air handling units, cooling towers, and cooling coils, catering to industries like Textile, Cement, Power, Coal, and more.

These Mist Eliminators serve diverse purposes, including increasing humidity in supply air, reducing air temperature, and removing dust from the air supply, or a combination of these functions.

Manufactured from high-quality PVC in India, our eliminators ensure trouble-free service over the years. The material is recommended for a maximum continuous operating temperature of 60°C, reflecting the inherent properties of Poly Vinyl Chloride.

The eliminators can be customized in terms of length. Customers can choose between corrugated cartons with jute packing for cost-effective packing suitable for normal road transport, albeit with a risk of breakage during transit, or wooden crates providing better protection but incurring higher packing and transportation costs due to increased weight and volume.

Installation of eliminators involves fixing them into spacer bars, notched plates, or combs attached to PVC stiffeners or G.I. angles supported on side walls. Our innovative fixing material encases all load-bearing M.S. material in PVC, eliminating the need for costly hot-dip galvanizing. While maintaining the basic design of the existing system, the modification reduces the impact of corrosion, and efforts have been made to minimize bolting requirements where possible.